|

工控产品 |

|

|

|

|

|

|

Mitsubishi_QnA Series

MELSECA/QnA Series |

|

|

|

|

|

|

|

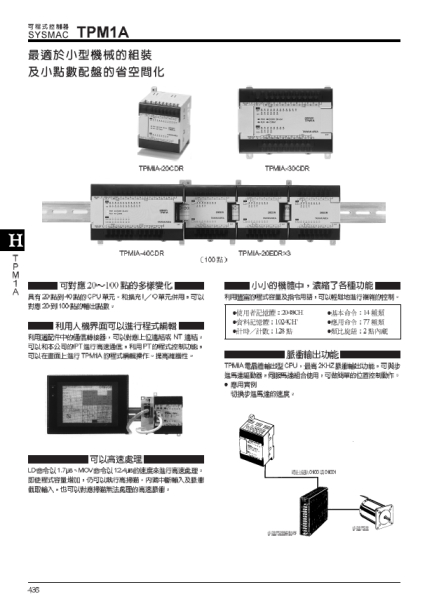

OMRON_TPM1A Series

|

|

|

|

|

|

|

|

AB-ControlLogix Selection Guide

The ControlLogix system provides sequential, process, motion, and drive control together with communications and state-of-the-art I/O in a small, cost-competitive package. The system is modular, so you can design, build, and modify it efficiently - with significant savings in training and engineering. A simple ControlLogix system consists of a standalone controller and I/O modules in a single chassis. |

|

|

|

|

|

|

|

AB_1753 Series

The GuardPLC system is a state of the art safety system offering the fastest safety PLCs, fastest controller throughput, and fastest safety network available. Designed in accordance with IEC 61131, the GuardPLC system meets the worldwide standard for programmable controls. It complies with many of the latest global safety standards and the worldwide standard for functional safety in programmable electronic systems. The GuardPLC system can be used without restriction in applications up to Category 4 according to EN-954 and Safety Integrity Level 3 (SIL 3) according to IEC 61508 |

|

|

|

|

|

|

|

AB_SLC-500

The Allen-Bradley SLC 500 is a small chassis-based family of programmable controllers, discrete, analog, and specialty I/O, and peripheral devices. The SLC 500 family delivers power and flexibility with a wide range of communication configurations, features, and memory options. The RSLogix 500 ladder logic programming package provides flexible editors, point-and-click I/O configuration, and a powerful database editor, as well as diagnostic and troubleshooting tools to help you save project development time and maximize productivity. |

|

|

|

|

|

|

|

FUJI_ POD UG Series

|

|

|

|

|

|

|

|

IFIX_Proficy Change Management

Proficy Change Management provides the functionality to manage and maintain programs and projects in a manufacturing environment to improve plant uptime, enforce good engineering practice and reduce risk. Using Version Control, Security, Audit Trailing, and scheduled verifications, you can get a handle on what’s happening in your plant. iFIX 4.0 and Proficy Change Management together provide a powerful way to manage your GE Fanuc HMI/SCADA applications and help make sure you never experience lost files and inability to recover from a disaster again. Proficy Change Management is also designed to be open and flexible interfacing with a variety of software and hardware products from various vendors in the automation industry including GE Fanuc, Rockwell, Siemens, Schneider and more. |

|

|

|

|

|

|

|

InTouch - Industrial Application Server Guide

If you are a current FactorySuite user, you very likely already have a system in place that works to your satisfaction. However, you may be considering an expansion or addition to your site using the latest technology: FactorySuite A2 and the Industrial Application Server. |

|

|

|

|

|

|

|

Intouch 9.5 Visualization Software

Wonderware’s InTouch 9.5 visualization software combines the world’s leading HMI software with cutting-edge graphical advances to enable customers to obtain tremendous improvements in operational and engineering productivity. The InTouch 9.5 HMI continues to outshine its competition with advances that include easy-to-use, object-oriented programmable graphics and powerful communication connectivity. InTouch software is an open and extensible HMI that enables flexibility in custom application design with connectivity to the broadest set of automation devices in the industry. |

|

|

|

|

|

|

|

Intouch_9.0 Visualization Software

Wonderware’s InTouch® 9.0 visualization software is a powerful graphical human-machine interface (HMI) for industrial automation, process control and supervisory monitoring. The InTouch HMI enables users to visualize and control industrial processes while providing engineers with an easy-to-use development environment and extensive functionality to rapidly create, test and deploy powerful automation applications that connect and deliver realtime information. InTouch software is an open and extensible HMI that enables flexibility in custom application design with connectivity to the broadest set of automation devices in the industry. |

|

|

|

|

|

|